Research under way in IU biology professor David Kehoe’s lab in Jordan Hall could result in a scientific “win-win-win,” a process that would reduce carbon dioxide in the atmosphere, produce commercially valuable chemicals and convert the resulting biomass to usable energy.

The Cyanobacteria Production Systems project is part of the IU Grand Challenges Preparing for Environmental Change initiative launched last year to help governments, businesses, nonprofits and individuals adapt to change.

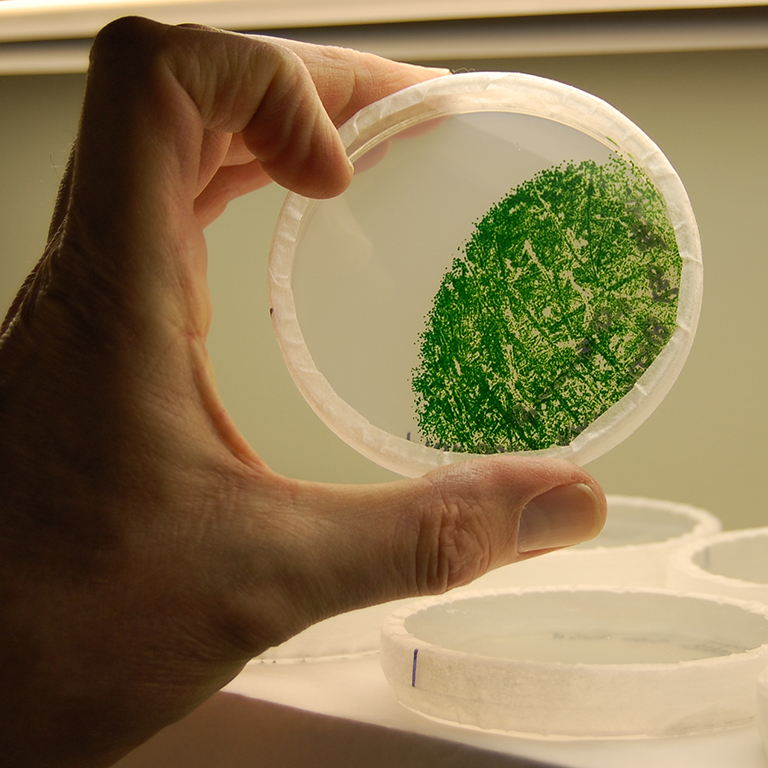

Kehoe says that cyanobacteria can play a significant role in helping the biomedical industry produce products sustainably through greener processes than are currently used. The single cell organisms are found everywhere, in soils and oceans, and they use photosynthesis to produce oxygen, consuming carbon dioxide in the process.

“Cyanobacteria already have changed the world,” says Kehoe. Billions of years ago, the rise of a new type of photosynthesis in cyanobacteria released huge amounts of oxygen into earth’s atmosphere and led to the extinction of most life on the planet, a phenomenon scientists call the Great Oxygenation Event. As oxygen levels rose, the environment changed dramatically, eventually giving rise to oxygen-consuming organisms, such as ourselves.

Now, Kehoe is exploring cyanobacteria’s potential to make another big change: reducing the amount of carbon dioxide in the atmosphere, helping to solve what he calls the “biggest environmental problem we currently face as humans.”

“We want to try to use cyanobacteria to reduce the amount of carbon dioxide in the environment by letting cyanobacteria do what they do naturally: use it to grow,” he says.

Kehoe’s research aims to engineer cyanobacteria to produce chemicals, such as pharmaceuticals, that are valuable to society and are commercially viable. Using plants and algae for this purpose is not a new idea, as several companies have moved in this direction. But variable production and yields and effective extraction have been problematic, making the use of such organisms challenging. Other organisms used in industry today are not photosynthetic but instead have to be fed, actually producing carbon dioxide and using man-made energy to sustain the process.

Advances in methodology have spurred scientists like Kehoe to reconsider cyanobacteria. Previously, cyanobacteria were known to be “stubborn” in the microbial world, difficult to modify to produce a chemical. But in the last 10 to 15 years, “we’ve seen a large improvement thanks to new techniques,” he said. “We now can use genetic engineering to modify cyanobacteria in many ways.”

Still, cyanobacteria have not drawn interest in terms of funding for biotechnology uses, which makes pursuing projects such as this one challenging. Kehoe says funding opportunities are more likely to focus on using plants develop commercial products.

“But Grand Challenges funding has opened the door for our efforts,” Kehoe says.

He already had been exploring industrial uses of cyanobacteria, but his research program has been able to advance with support from the Environmental Resilience Institute, funded as part IU’s $55 million Prepared for Environmental Change Grand Challenge initiative.

“One of the purposes of our Environmental Resilience Institute is to develop and offer to society alternative ways of doing things that help the environment and are as good or better economically than what is in use now,” Kehoe says. “No one running a company or producing power will invest in a process on the off chance it will work. We have to show results.”

Kehoe has spent his career exploring biological processes, and this is his first experience directing his work toward a commercial goal. The science is exactly the same, he says, but to understand how business innovation functions, he turned to experts. Rather than risk pursuing a product that would not be valued in the biomedical or industrial world, he wanted to understand what types of chemicals would be attractive to businesses.

Kehoe partnered with Jaipal Singh, director of the Indiana Center for Biomedical Innovation at IUPUI, and Peter Schubert, a professor and the director of the Richard G. Lugar Center of Renewable Energy at IUPUI, for guidance on how to direct his research with an eye toward commercial enterprise.

Singh was drawn to Kehoe’s idea, and the two now are collaborating on grant funding options.

“Our mission is to create therapies for patients by taking early stage research at IU’s School of Medicine and translate that to patient care,” Singh said of the Indiana Center for Biomedical Innovation, which serves as a business incubator that taps into the expertise of numerous medical and pharmaceutical companies. “Kehoe’s system was interesting to us as it could be utilized for making pharmaceuticals. And it’s a good synergy in that he has technology, and we can extend the testing using various assays and systems we already have in place.”

Businesses work with the center, Singh says, because they are looking not only for innovations, but also cost containment and sustainability – and many are open to investing in fledgling, but promising, projects.

Schubert of the Lugar Center bridges the academic world and industry. He says the cyanobacteria project fits well with his own research into using bacteria to clean carbon dioxide from smokestacks. And, Kehoe said, Schubert contributed to the third part of the “win-win-win” by asking Kehoe what would happen to the “sludge,” the biomass left after a new chemical is extracted from the cyanobacteria.

“My personal research has sought to convert dead biomass to energy,” Schubert says, “so I saw a dangling opportunity when David described this project: What will you do with the dead cyanobacteria after it produces your chemicals?”

The answer is to convert the sludge into energy. Schubert says that through gasification, sludge can produce electricity to help run the operation, so that the whole process would become nearly self-sufficient. Even the very last bit, the “bio char,” a chemically non-reactive substance, can be used as soil augmentation and to help retain moisture, as well as sequester carbon in the ground.

All of these strategies depend on which chemicals they decide to produce and their usefulness in the industry, and the process is slow, the researchers say. But the results could mean eventually changing the way industry operates and contributing to a more sustainable world.

“We have to demonstrate that we can provide efficient and cost-effective products, and do that as well or better than those using traditional organisms,” Kehoe says. “We want to develop processes that are turn-key commercially, so we can say to companies, ‘Here’s how to get this product and help the environment.’ That’s our challenge.”